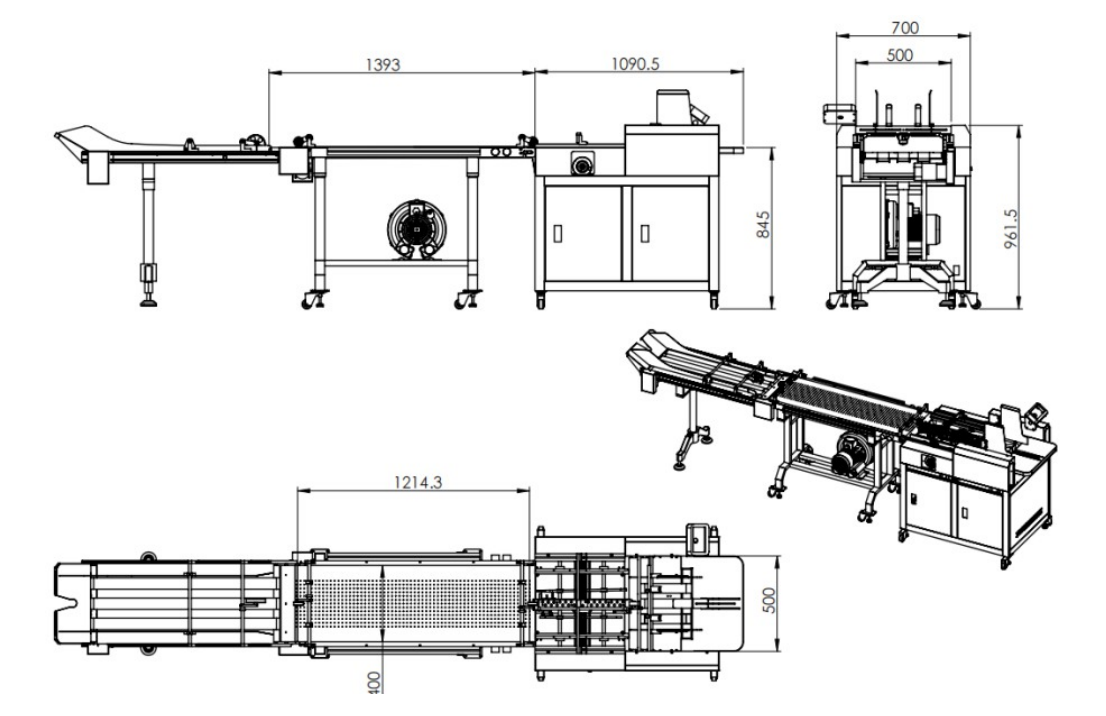

Automatic correcting and paging machine

Current model: IPM203ST-400S

The intelligent paging UV printing platform product adopts the friction principle to realize paging feeding, including paging feeding, corona & printing negative pressure conveying, high temperature resistant curing line, automatic collection and other standard "four-section" structure. The whole machine adopts stainless steel material combined with streamline design style, and the supporting detachable floor bracket is convenient for packaging, saving transportation cost and use space. The unique paging structure design makes the product adaptable, easy to adjust and easy to operate. And it has rich matching functions to meet various application requirements. Compared with the "standard intelligent paging UV printing platform", this model has higher cost performance. Widely suitable for: paper, labels, cartons, ordinary plastic bags and other packaging products to complete UV printing; It can also be equipped with CIJ (small character), TIJ (high resolution) and other inkjet printers, plane labeling machines, laser coding machines to print various texts, patterns and other contents according to needs.

Product Classification:

Key words:

paging machine

- Product Description

-

The intelligent paging UV printing platform product adopts the friction principle to realize paging feeding, including paging feeding, corona & printing negative pressure conveying, high temperature resistant curing line, automatic collection and other standard "four-section" structure. The whole machine adopts stainless steel material combined with streamline design style, and the supporting detachable floor bracket is convenient for packaging, saving transportation cost and use space. The unique paging structure design makes the product adaptable, easy to adjust and easy to operate. And it has rich matching functions to meet various application requirements. Compared with the "standard intelligent paging UV printing platform", this model has higher cost performance. Widely suitable for: paper, labels, cartons, ordinary plastic bags and other packaging products to complete UV printing; It can also be equipped with CIJ (small character), TIJ (high resolution) and other inkjet printers, plane labeling machines, laser coding machines to print various texts, patterns and other contents according to needs.

The intelligent paging UV printing platform product adopts the friction principle to realize paging feeding, including paging feeding, corona & printing negative pressure conveying, high temperature resistant curing line, automatic collection and other standard "four-section" structure. The whole machine adopts stainless steel material combined with streamline design style, and the supporting detachable floor bracket is convenient for packaging, saving transportation cost and use space. The unique paging structure design makes the product adaptable, easy to adjust and easy to operate. And it has rich matching functions to meet various application requirements. Compared with the "standard intelligent paging UV printing platform", this model has higher cost performance. Widely suitable for: paper, labels, cartons, ordinary plastic bags and other packaging products to complete UV printing; It can also be equipped with CIJ (small character), TIJ (high resolution) and other inkjet printers, plane labeling machines, laser coding machines to print various texts, patterns and other contents according to needs.

Standard configuration Optional Configuration Friction type paging discharge TIJ/Uv Jet Printing/Laser Coding_Third Party High-speed conveyor belt Plasma Processors-Third Parties automatic correction visual inspection negative pressure adsorption Online automatic labeling_third party Counting function Automatic rejection Support customization

Installation method

Paging support cabinet type

Conveying support frame

Body material

Stainless Steel

Overall dimension

Length L * Width W * Height H ≈

3000 × 700 × 1200mm

Input power

220VAC

Equipment weight

About 200KG

Collection Method

Collection hopper drop stacking material collection

Conveyor belt width

400mm

Control mode

Ifeeder dedicated controller

or PLC control

Input power

About 2000W

Paging machine only, excluding coding machine

Efficiency

According to the actual product size

Post-test decision

Belt running speed

0-80 m m/min min

Transmission mode

Variable frequency speed control or DC brushless speed control

Conveyor belt length optional

1000mm

Negative pressure adsorption optional

Fan

fan

Adapt to product size range

Length L * Width W * Thick THK ≈

(60-300)×(30-400)×(0.1-3)mmWarranty period: 1 year (except for wearing parts)

Vulnerable parts: paging friction belt and paging friction belt

Random accessories: power cord 1, paging friction pressure belt 1

Related Products