TTO Rewinder

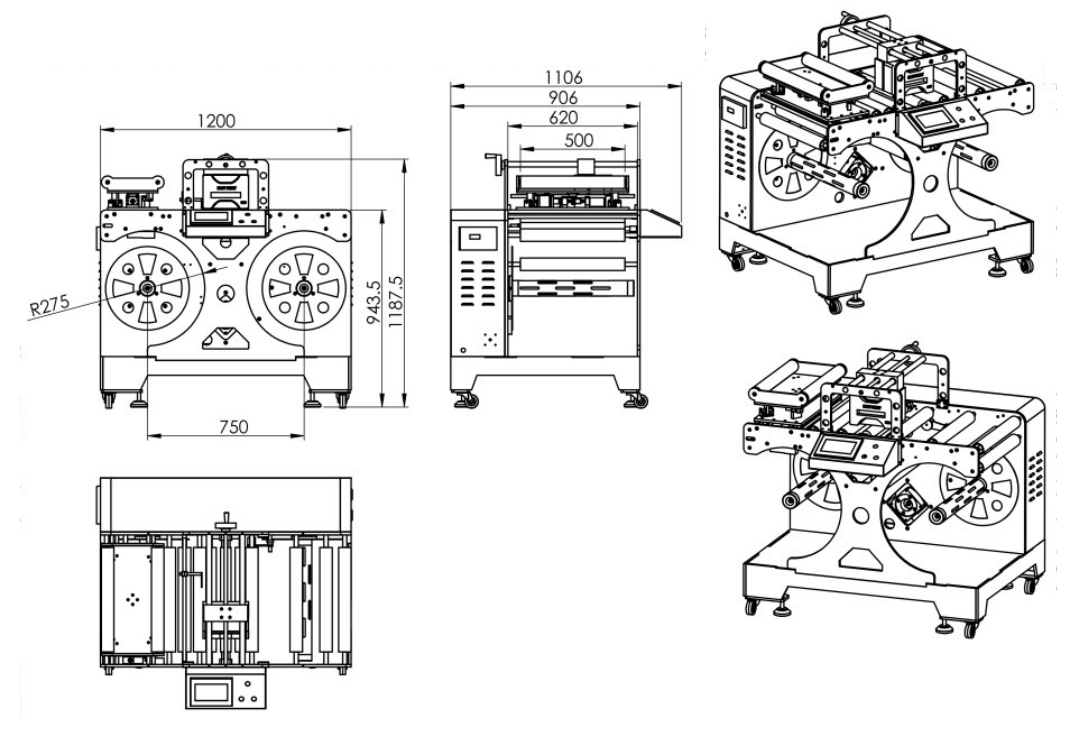

Current model: IF-RW500ST

According to the characteristics of thermal transfer coding process, it is specially developed and produced, and TTO printing rubber roller and printer mounting bracket are configured. The man-machine interface adopts 7-inch color touch screen, PLC and microcomputer control. According to the requirements of knot and performance difference of various roll films and roll labels, the touch screen sets working parameters, monitors working conditions and provides alarm reminders, the control system has all functions such as linear unwinding and winding tension, fast/slow lifting, parking anti-loosening, white mark or color mark triggering induction, counting, etc., to truly realize intelligent control.

Product Classification:

Key words:

TTO Rewinder

- Product Description

-

According to the characteristics of thermal transfer coding process, it is specially developed and produced, and TTO printing rubber roller and printer mounting bracket are configured. The man-machine interface adopts 7-inch color touch screen, PLC and microcomputer control. According to the requirements of knot and performance difference of various roll films and roll labels, the touch screen sets working parameters, monitors working conditions and provides alarm reminders, the control system has all functions such as linear unwinding and winding tension, fast/slow lifting, parking anti-loosening, white mark or color mark triggering induction, counting, etc., to truly realize intelligent control.

According to the characteristics of thermal transfer coding process, it is specially developed and produced, and TTO printing rubber roller and printer mounting bracket are configured. The man-machine interface adopts 7-inch color touch screen, PLC and microcomputer control. According to the requirements of knot and performance difference of various roll films and roll labels, the touch screen sets working parameters, monitors working conditions and provides alarm reminders, the control system has all functions such as linear unwinding and winding tension, fast/slow lifting, parking anti-loosening, white mark or color mark triggering induction, counting, etc., to truly realize intelligent control.

Standard configuration Optional Configuration Single device High precision frame type correction system TTO coding machine

Installation method

Floor bearing bracket

Body material

Standard carbon steel paint

Optional stainless steel

Collection Method

automatic rewinding

Input power

220VAC

Equipment weight

About 300KG

Input power

Approximately ≈ 1.5-2KW

Efficiency

According to the actual product size

Post-test decision

Control mode

Standard manual tension control

Optional automatic tension control

Transmission mode

AC servo motor

Material thickness

0.012-0.15mm

Running speed

1-100 m/min

Maximum diameter of material

500mm

rewinding accuracy

≤ ± 0.2mm

Depending on the material and speed,

Must be equipped with correction system

Material Paper Core Inner Diameter

3 inches

Material width

30-500mm

Applicable Materials

BOPP, CPP, PET, PE, paper, composite film, aluminum film and other roll-shaped materialsWarranty period: 1 year (except for wearing parts)

Vulnerable parts: gas pipe joint

Random accessories: 1 power cord, 1 tension trachea

Related Products