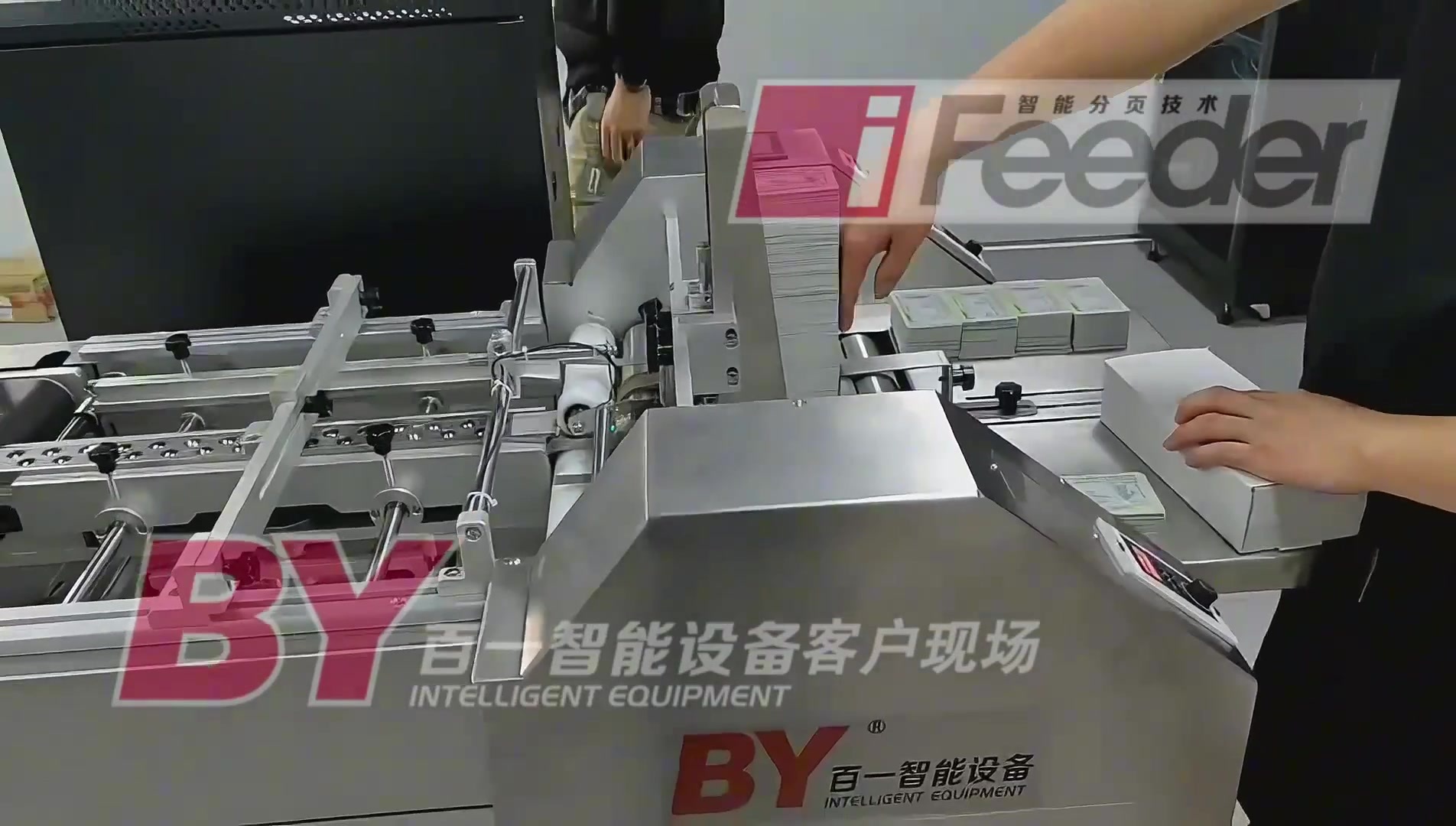

Card UV Jet Printing Visual Inspection Automatic Labeling Correcting Paging Machine Customer Application Site

Release time:

2024-04-19

PCV cards, exchange cards, shopping cards, loyalty cards, gift cards, supermarket cards, etc.

In recent years, with the increasing number of cash cards exchanged for gifts and commodities, the number of cards printed has increased significantly. In this regard, we visited nearly 1,000 card manufacturers around the world and found that nearly 90% of the factories print or label cards by manual feeding.

While collecting opinions from factories, we have successfully developed this: high-speed friction feeding inkjet printing, photo detection and labeling integrated system

What are its components?

1. High-speed friction feeder: As the main operating platform, it has a 260mm high storage bin. Workers only need to continuously stack materials into the storage bin. The products are transferred to the automatic correction mechanism one by one through friction for position correction, and then transferred to the conveyor belt;

After a series of inkjet printer photo tests are carried out on the conveyor belt, if the product is unqualified or not printed, the system will not send the next labeling action to the product, and the product will go directly to the automatic exit organization as the eliminated product;

If the product is qualified in printing and testing, the system will issue a labeling action on the product and smoothly enter the storage mechanism of the qualified product after labeling.

2. UV inkjet printer: mainly composed of plasma processor (stronger ink adhesion on the surface) UV inkjet print head and control cabinet UV curing lamp (drying)

3, visual inspection system: mainly composed of camera display keyboard and mouse real-time camera detection system

4. Automatic labeling system: complete labeling mechanism and system

What are the effects of this system on card manufacturers?

The speed of the automatic feeder is much higher than that of manual feeding, and the output and efficiency are greatly increased.

The visual inspection system replaces manual inspection one by one to check whether the printed content is wrong, missing or not printed.